universal walking foot sewing machine

Latest articles

universal walking foot sewing machine4. Pins and Clips Traditional pins may struggle to hold heavy canvas as securely as needed. Use heavier-duty clips, like Wonder Clips, to keep your fabric in place during sewing.

...

universal walking foot sewing machine 【universal walking foot sewing machine】

Read More

universal walking foot sewing machineConclusion

...

universal walking foot sewing machine 【universal walking foot sewing machine】

Read More

universal walking foot sewing machineZig zag embroidery is characterized by its unique stitch pattern that resembles a ‘Z’ shape. This technique is not only decorative but also serves a functional purpose, primarily in reinforcing seams and preventing fabric fraying. The industrial zig zag embroidery machine is equipped with sophisticated technology that allows for various stitch types, including regular zig zag, satin stitches, and other decorative patterns. This adaptability enables businesses to create diverse designs suitable for a range of applications, from fashion apparel to home textiles.

...

universal walking foot sewing machine 【universal walking foot sewing machine】

Read More

...

universal walking foot sewing machine 【universal walking foot sewing machine】

Read MoreAutomotive sewing machines are designed specifically for the demands of the automotive industry. They are typically constructed to handle thick and layered materials like leather, synthetic fabrics, and foam, which are commonly used in car interiors. These machines often come with specialized attachments and stitching patterns that cater to a wide variety of tasks, from sewing intricate seat designs to creating durable door panels.

automotive sewing machine

universal walking foot sewing machine

...

universal walking foot sewing machine 【universal walking foot sewing machine】

Read MoreAnother significant benefit is efficiency. With the ability to handle various fabric types and thicknesses, needle feed sewing machines streamline the production process, reducing the need for multiple machines and improving workflow in a manufacturing setting. This efficiency is especially crucial in today's fast-paced fashion landscape, where time-to-market is a critical factor for success.

universal walking foot sewing machine

...

universal walking foot sewing machine 【universal walking foot sewing machine】

Read MoreIn the world of garment manufacturing and textile production, advanced machinery plays a crucial role in enhancing efficiency, quality, and speed. Among the many specialized machines utilized, the 3-needle chain stitch machine stands out as a vital tool for achieving durable and high-quality seam finishes. This article will explore the features, benefits, and applications of the 3-needle chain stitch machine, underscoring its significance in the modern textile industry.

universal walking foot sewing machine

...

universal walking foot sewing machine 【universal walking foot sewing machine】

Read More4. Reduced Labor Intensity The physical strain associated with hand stitching leather can be significant, especially for large projects. By utilizing stitching machines, artisans can reduce their manual workload, allowing them to focus on more creative aspects of their craft.

universal walking foot sewing machine

...

universal walking foot sewing machine 【universal walking foot sewing machine】

Read MoreOne of the main benefits of a double foot sewing machine is its ability to sew multiple layers of fabric at once. This is especially useful when working on projects that require thick or heavy materials, such as denim or leather. The dual feed system helps to prevent fabric from shifting or puckering as it passes under the needle, resulting in clean and professional-looking seams.

universal walking foot sewing machine...

universal walking foot sewing machine 【universal walking foot sewing machine】

Read MoreA heavy-duty sewing machine can be an investment that pays for itself. But be sure to do the research before buying!

universal walking foot sewing machine

...

universal walking foot sewing machine 【universal walking foot sewing machine】

Read MoreLatest articles

-

5. After-Sales Support Companies that offer comprehensive after-sales support, including installation, training, and maintenance services, may charge more for their machines. However, this support can be invaluable for ensuring optimal performance and longevity of the equipment.

-

-

Quilting and Crafts

Additionally, many models are designed with intuitive controls and clear instructions, which help new sewists become proficient in a short time. This focus on user-friendliness empowers beginners to explore their creativity without feeling overwhelmed by complex operations.

To get started with chain stitching, one needs basic sewing tools fabric, appropriate thread, and a sewing machine or needle for hand stitching. Selecting the right type of thread is crucial, as the thread should complement the fabric’s texture and weight. The proper tension settings on the sewing machine are essential for achieving a flawless chain stitch and preventing issues like thread breakage or puckering.

Links

Conclusion

Eco-Friendly Option

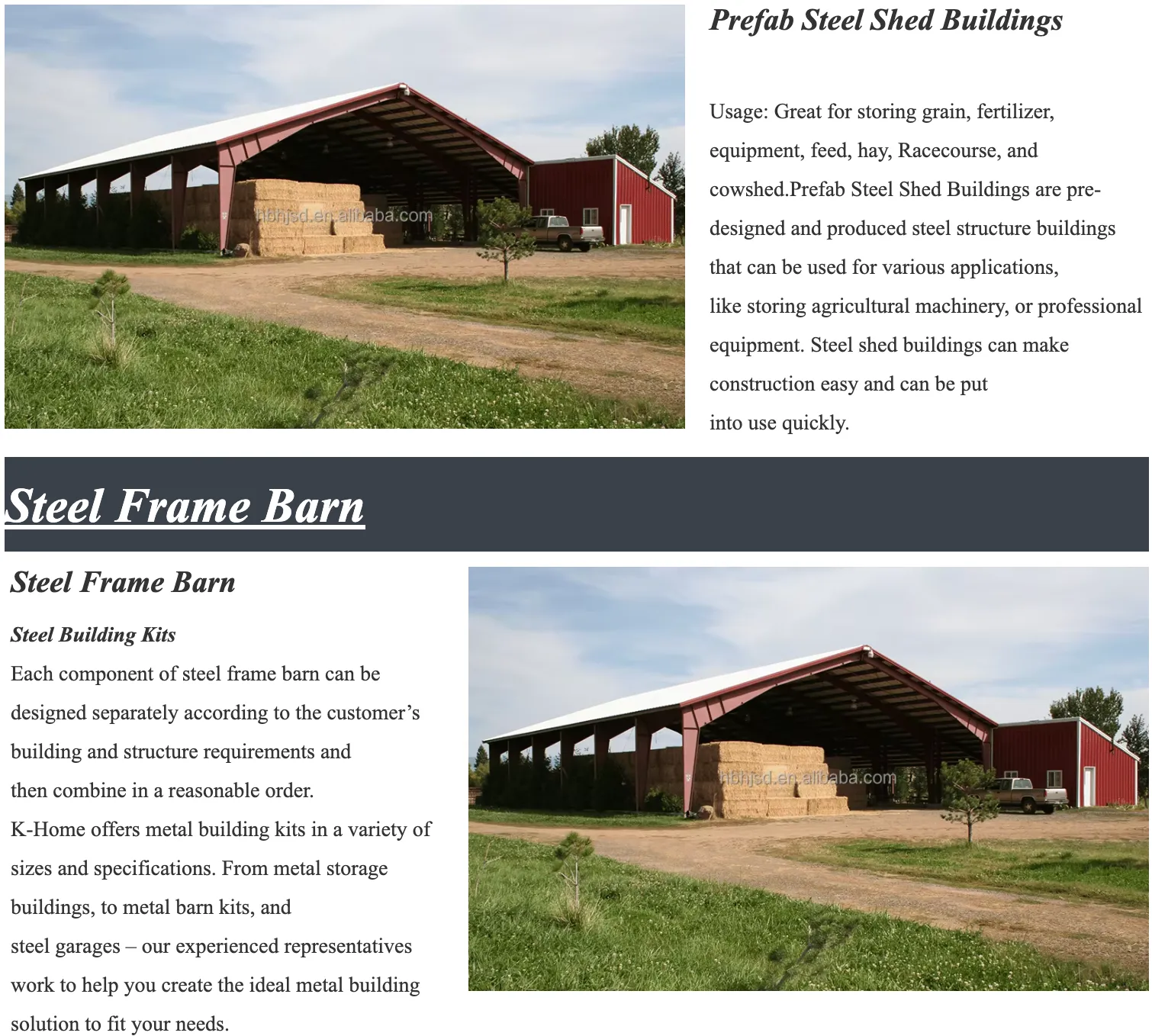

Additional Benefits of Steel Warehouses

One of the most compelling reasons for the popularity of steel frame barn houses is their durability. Steel is inherently resistant to common issues that plague traditional wooden structures, such as rot, pests, and warping. This resilience ensures that a steel frame barn house can withstand the test of time, making it an excellent choice for those looking for a long-term investment in their living space. Unlike wooden houses, which may require regular maintenance and repairs, steel frame homes can minimize these burdens, allowing homeowners to enjoy their property without the constant worry of upkeep.

Versatility and Customization

In addition to their ecological benefits, small steel office buildings also offer cost-effectiveness. The initial investment in steel construction may be slightly higher than traditional materials, but the long-term savings in maintenance, energy efficiency, and durability often outweigh these initial costs. Furthermore, businesses benefit from lower insurance premiums due to the robustness of steel structures. All these factors contribute to an appealing total cost of ownership, making small steel office buildings an attractive option for companies looking to maximize their financial resources.

When it comes to storage solutions, large metal sheds and workshops have emerged as a popular choice for both homeowners and businesses. These durable structures provide a versatile space for a wide range of activities, from simple storage to complex workshop tasks. Here, we delve into the benefits of large metal sheds and workshops, highlighting why they are an excellent investment for various needs.

Agriculture has long been the backbone of economies and societies worldwide. As the industry evolves to meet the demands of a growing population and the challenges of climate change, the materials used in agricultural construction are also changing. One material that has gained significant traction in agricultural buildings is metal. Its advantages make it a preferred choice for farmers and agricultural businesses alike.

As we move forward into an era of innovation and practicality, Metal Garages Direct stands out as a reliable provider of metal garages that combine quality, efficiency, and customization. Their model not only meets the contemporary demands of storage and shelter solutions but does so with a dedication to customer satisfaction. For anyone in need of a robust and versatile garage option, Metal Garages Direct is unquestionably a leader in the market, ready to provide the ideal solution for storage needs. With their focus on affordability and quality, it is clear why more customers are turning to metal garages as their preferred choice for shelter.

Understanding Factory Direct Steel Buildings

One of the most compelling reasons for choosing corrugated metal for barn construction is its robustness. Made from steel or aluminum, this material is designed to withstand harsh environmental conditions. It is resistant to extreme weather, including heavy rain, strong winds, and even hail. Unlike traditional wood, which can rot, warp, or be infested by pests, corrugated metal maintains its integrity over time. This strength not only ensures the longevity of the barn but also provides a safe environment for livestock and storage.

In recent years, the popularity of steel frame barns has surged among farmers, ranchers, and those seeking versatile storage solutions. These structures offer numerous benefits, such as durability, low maintenance, and versatility in design. However, understanding the costs associated with building a steel frame barn is crucial for anyone considering this investment.

In an age where sustainability is becoming increasingly important, metal buildings stand out as an environmentally friendly option. Steel is a recyclable material, and many metal barns are constructed with a significant percentage of recycled steel. This reduces the need for new materials and decreases the overall carbon footprint of the building process. Additionally, metal barns can be designed with energy-efficient features such as insulated panels that contribute to reduced heating and cooling costs.

Easy Maintenance

Another critical aspect of metal warehouse kits is their ease of assembly and reconfiguration. Many kits come with pre-drilled holes and easy-to-follow instructions, allowing for quick setup and dismantling. This is particularly advantageous for businesses that may need to rearrange their storage layout frequently based on changing inventory levels or operational needs. The ability to quickly adapt to new requirements ensures that companies can remain agile and responsive in a competitive marketplace.

The Benefits of a Metal Garage for Your Car

Sustainability is a crucial consideration in today’s construction practices, and prefab steel structure buildings align well with these environmental goals. Steel is one of the most recyclable materials available, allowing for its use in green building initiatives. The ability to recycle steel not only reduces waste but also minimizes the carbon footprint associated with the extraction and production of new materials.

3. Location The geographic location of the construction site plays a crucial role in pricing. Transportation costs for the prefabricated components can rise significantly for remote areas, and local regulations might require additional permits or inspections.

The first step in designing an effective layout is to understand the workflow. In a typical steel fabrication workshop, the process generally involves several stages, including cutting, shaping, welding, finishing, and assembly. Each stage requires specific equipment and space considerations. A streamlined workflow minimizes the distance materials and workers must travel, thereby reducing time waste and increasing efficiency.

The adaptability of steel structures to different environments and functional requirements is another crucial attribute. As industries evolve, so do their spatial needs. Steel buildings can be easily modified or expanded without significant structural changes. Walls can be added or removed, and additional floors can be constructed with relative ease. This flexibility ensures that businesses can adapt to changing demands without the disruption of extensive renovations.

Functionality is another key factor driving the popularity of red and grey pole barns. These buildings can serve a multitude of purposes from storage for farming equipment, livestock shelters, and workshops, to event venues, garages, and even homes. The open interior space allows for customizable layouts, enabling owners to adapt the barn to their specific needs. For instance, many choose to incorporate large doors and ample windows, creating an airy environment that can be easily modified for various activities.

red and grey pole barn

In today's world, where creativity meets functionality, the metal garage shop stands out as a remarkable space that blends craftsmanship with innovative design. Whether it's for a DIY enthusiast, a professional fabricator, or a hobbyist, a metal garage shop serves as an ideal environment to express one’s skills while working on a variety of projects.

Efficient On-Site Assembly Techniques

Conclusion

Modern Agricultural Buildings Innovations in Design and Functionality

Eco-Friendly Option

Advantages of Prefab Steel Shops

In addition to their resilience, metal frame pole barns are also cost-effective. The materials used in their construction are generally less expensive than traditional building materials, and because the construction process is often quicker, labor costs can also be reduced. This efficiency not only saves money but also allows for faster occupancy, making it a suitable option for businesses that need immediate space.

Many manufacturers offer a range of services, from design and fabrication to installation. This integrated approach ensures that the entire process is streamlined, resulting in higher quality outcomes. Moreover, these companies often provide comprehensive support throughout the building's lifecycle, including maintenance services and upgrading options, making them valuable partners in the construction industry.

While functionality is essential, the appearance of agricultural buildings should not be overlooked. Steel poultry sheds can be designed to be visually appealing, blending seamlessly into the rural landscape. With various cladding options and colors available, farmers can create attractive and professional-looking poultry houses that enhance the aesthetics of their properties.

The Gambrel Barn Design

1. Manufacturing Facilities

In recent years, the popularity of prefabricated metal buildings has surged, largely due to their affordability, durability, and easy maintenance. As businesses and homeowners alike seek flexible, cost-effective solutions for various needs—be it commercial, industrial, or residential—the prices of these pre-engineered structures have become a critical consideration. This article will explore the factors influencing the prices of prefabricated metal buildings, providing insights for potential buyers.

In today's world, sustainability is more important than ever. A metal workshop that includes living quarters can also incorporate eco-friendly practices. Using sustainable materials, implementing solar panels, and creating recycling stations for metal scraps are just a few ways to ensure that craftsmanship does not come at the expense of the environment.

Custom metal buildings are a somewhat heftier investment. But with a building designed to match your company’s services and policies, it brings a touch of competitive pricing.

Another notable benefit of narrow metal sheds is their low maintenance requirements. Unlike wooden sheds, which demand regular treatments to prevent decay and protect against pests, metal sheds require far less upkeep. A simple wash with soap and water is often sufficient to keep them looking good. Over time, this ease of maintenance translates to both time and cost savings for the homeowner, allowing individuals to focus more on enjoying their outdoor spaces rather than worrying about upkeep.